Have you ever received a business envelope with a small circular sticker on the flap? That’s called a wafer seal. It may seem like just another piece of paper, but it actually serves an important purpose in the world of mailing and shipping.

In this article, we’ll dive into everything you need to know about wafer seals – what they are, why they’re used, and how to use them properly. Whether you’re a business owner preparing mailings or someone who frequently receives mail, understanding this little disc can save you time and frustration. So let’s get started and learn all about the versatile wafer seal!

So, wafer seal?

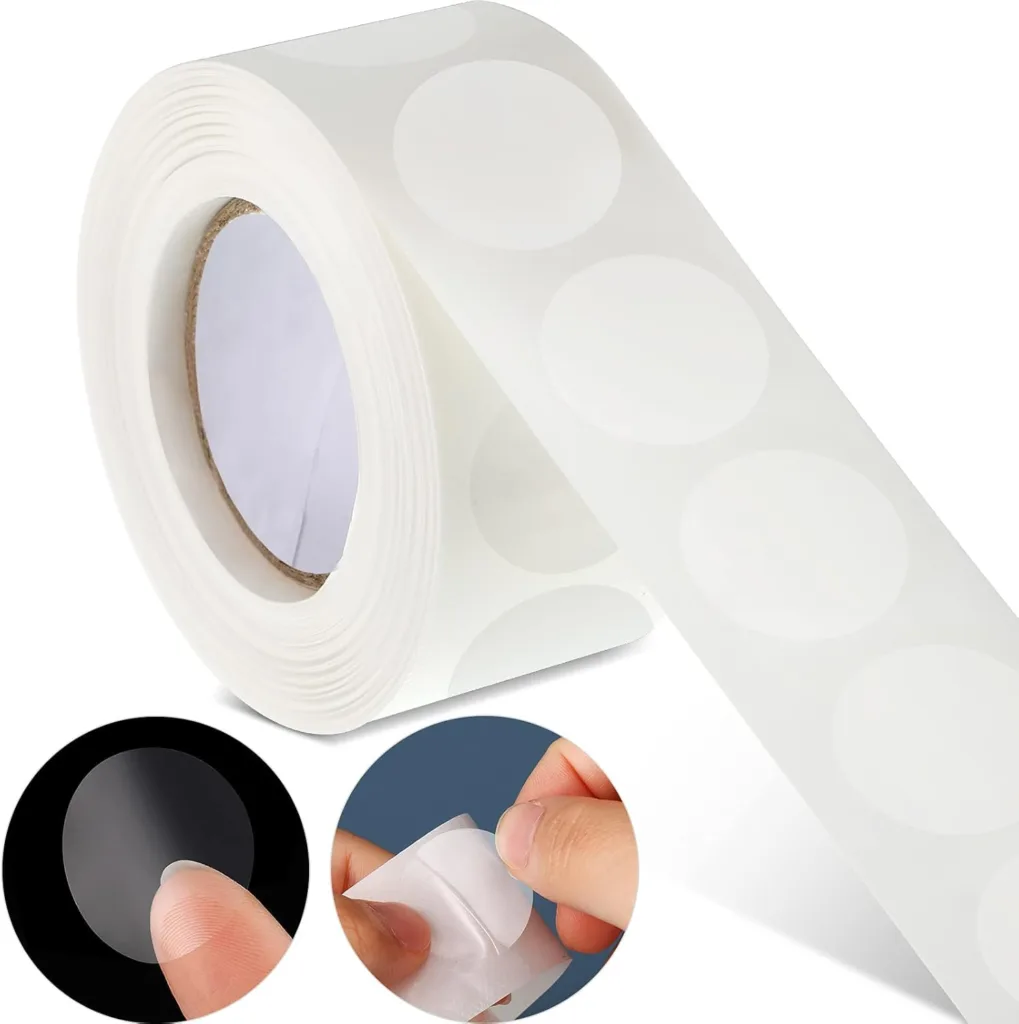

A wafer seal is a small circular sticker used to secure envelopes or packages. It is typically made of paper, foil, or plastic and has an adhesive backing for easy application.

To use a wafer seal properly, first make sure the surface where you will be placing it is clean and dry. Then peel off the backing and carefully press the seal onto the envelope or package, making sure it is centered and securely attached.

Wafer seals are commonly used in business settings to add a professional touch to mailings such as invoices, contracts, or promotional materials. They can also be used for personal correspondence like wedding invitations or holiday cards.

It’s important to note that while wafer seals do provide some level of security by preventing tampering with the contents inside, they are not considered completely tamper-proof. Therefore, it’s recommended to use additional measures such as tape or extra layers of packaging for sensitive documents.

In summary, a wafer seal is a simple yet effective tool for sealing envelopes and packages. With proper usage, it can enhance the appearance and security of your mailings.

Understanding the Purpose of a Wafer Seal

A wafer seal plays a crucial role in various manufacturing and packaging processes, especially in the food industry. This thin layer acts as an airtight barrier, ensuring that products remain fresh and uncontaminated. When you think about how many items we buy at the store, from snacks to medicines, it’s fascinating to realize that this simple yet effective seal is often responsible for their longevity and safety. By preventing moisture and air from entering, these seals help maintain flavor and quality over time. The materials used can vary but are typically designed to withstand different temperatures or conditions, making them highly versatile.

Moreover, wafer seals are not just functional; they also enhance product presentation. A well-applied seal gives off an impression of care and quality that customers appreciate. Consider when you open a package of cookies: there’s a sense of excitement when you hear that little “pop” sound as the seal breaks! These seals can be printed with branding elements too, allowing companies to convey important information while maintaining aesthetics.

- They provide tamper evidence

- Help reduce spoilage

- Ensure safety compliance

In essence, wafer seals embody both practicality and design elegance in everyday products we often take for granted.

Types and Materials of Wafer Seals

Wafer seals are essential components used in various industries, particularly in the fields of electronics and packaging. These seals come in different types, primarily designed to meet specific operational needs. The most common types include pressure-sensitive adhesive (PSA) wafer seals, which rely on a sticky surface that adheres upon contact; heat-sealable variants, which bond when exposed to high temperatures; and die-cut designs tailored for particular shapes or sizes. Each type offers unique advantages, making them suitable for diverse applications—from ensuring airtightness in food packaging to protecting delicate electronic components.

The materials used to create wafer seals play a vital role in determining their performance and durability. Commonly used materials encompass polyethylene terephthalate (PET), known for its excellent resistance to moisture and chemicals; polypropylene (PP), favored for its lightweight yet strong properties; and silicone-based films that provide exceptional flexibility.

- Each material brings something special.

- PET is tough against tears.

- PP is cost-effective while maintaining strength.

- Silicone adds versatility with its stretchiness.

By selecting the right combination of type and material, manufacturers can enhance product longevity while achieving reliable sealing solutions tailored to their specific requirements.

Read also: holdfast money maker

Proper Placement and Usage of Wafer Seals in Mailing

When it comes to mailing, the proper placement of wafer seals is essential for ensuring that packages arrive safely and securely. These thin discs, often made from paper or plastic, serve as a closure mechanism that keeps envelopes and boxes tightly sealed during transit. To achieve the best results, it’s crucial to apply them correctly. Ideally, you should place the wafer seal at the edge where two surfaces meet—this could be the flap of an envelope or the seams of a package. Positioning it about half an inch from the edge helps ensure maximum adhesion while also allowing for easy opening by recipients.

Additionally, understanding how to use these sealing devices effectively maximizes their benefits. Before applying a wafer seal, make sure both surfaces are clean and dry; any moisture or dust can hinder adhesion. For added security, consider using multiple seals on larger items or heavy packages.

When addressing your mailings, remember not to obstruct any important information with these seals; aim for areas where they won’t interfere with labels or stamps. This way, your correspondence remains professional and organized while also being secure against accidental openings in transit. By following these simple guidelines regarding placement and usage, you can enhance both safety and efficiency in your mailing process!

Benefits of Using a Wafer Seal for Business Owners

For business owners looking to enhance their packaging methods, a wafer seal offers numerous advantages that can elevate both product quality and customer satisfaction. These seals provide an airtight barrier, ensuring that products remain fresh and uncontaminated. This is especially beneficial for food-related businesses where freshness is paramount. With the use of wafer seals, items like snacks or baked goods maintain their flavor and texture longer, reducing waste and increasing sales potential. Furthermore, they are visually appealing; the sleek design often enhances the overall presentation of the product on store shelves.

Additionally, wafer seals contribute to increased security for packaged goods. They act as tamper-evident features which help reassure customers about the integrity of what they’re buying. When clients see a sealed package indicating no previous access to its contents, it builds trust in your brand’s reliability and commitment to quality.

- They reduce spoilage costs.

- They enhance brand reputation through professional appearance.

- They simplify inventory management.

All these factors combined make wafer seals not just a practical choice but also a savvy investment for any business owner aiming to stand out in today’s competitive market while providing top-notch service.

You may also like: who are Amazon Inc’s joint venture partners

Common Mistakes to Avoid When Applying a Wafer Seal

Applying a wafer seal can be a bit tricky, especially if you’re not familiar with the process. One of the most common mistakes is not cleaning the surfaces thoroughly before application. Dust, grease, or even tiny particles can create air pockets that compromise the seal’s effectiveness. To ensure optimal adhesion, it’s essential to wipe down both surfaces using an appropriate cleaner and allow them to dry completely. This simple step can make a world of difference in achieving a durable bond that lasts over time.

Another frequent error occurs when users underestimate the importance of applying consistent pressure during installation. When placing a wafer seal, it’s crucial to exert uniform force across its entire surface. If part of the seal is pressed too lightly while another section receives too much pressure, it may lead to uneven sealing and potential leaks later on. To help avoid this pitfall:

- Start from one end and work your way across.

- Use even strokes with your hands or tools.

- Check for proper alignment often as you go along.

This careful attention ensures that each layer adheres perfectly without unwanted gaps or bubbles forming underneath!