Thinking of expanding your printed goods business? Want to take it to the next level and dominate the market? One effective strategy that has been gaining traction in the industry is joint ventures.

In this article, we’ll delve into the world of joint ventures in the printed goods manufacturing industry and explore how this game-changing business strategy can benefit your company. From increased production capacity to accessing new markets and cutting costs, there are countless advantages that come with joining forces with another business. So if you’re ready to revolutionize your printing business, keep reading to learn all about joint ventures and why they are a smart move for any aspiring entrepreneur in the printed goods manufacturing industry.

So, joint ventures in additive manufacturing industry?

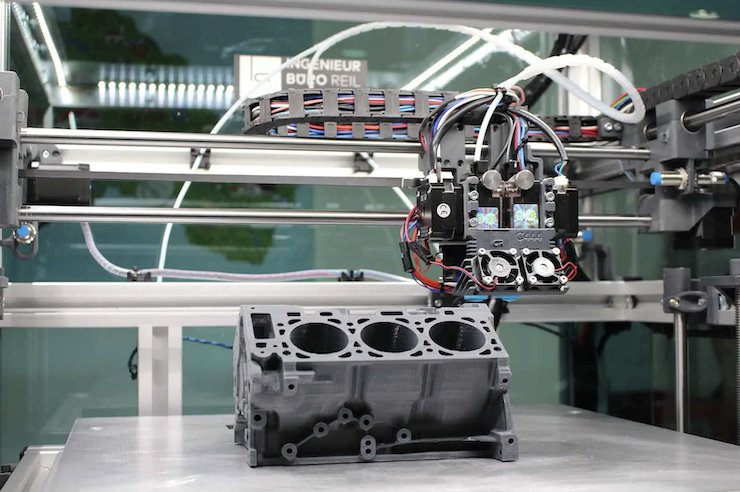

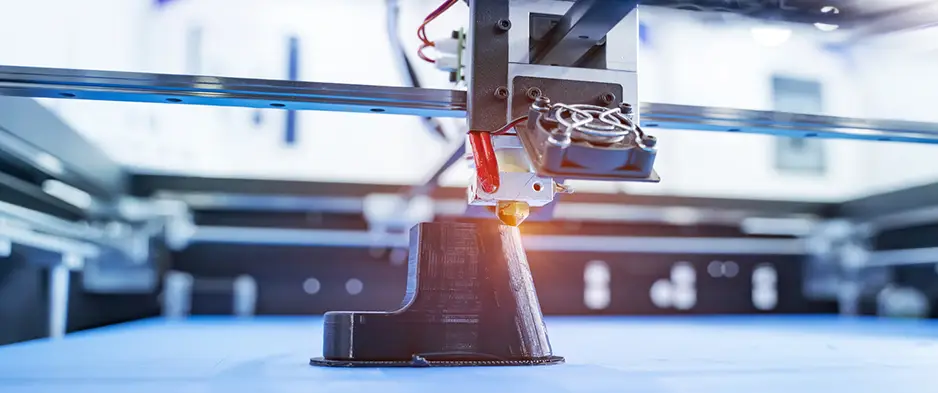

Joint ventures in the additive manufacturing industry have become increasingly popular in recent years, and for good reason. Additive manufacturing, also known as 3D printing, is a rapidly growing technology that has the potential to revolutionize various industries such as healthcare, aerospace, automotive, and more.

A joint venture is a strategic partnership between two or more companies that allows them to combine their resources and expertise to achieve a common goal. In the case of additive manufacturing, joint ventures can provide access to new markets and technologies while reducing costs and risks.

One key benefit of joint ventures in this industry is the ability for companies to pool their resources together. This can include sharing expensive equipment or materials, which can be especially beneficial for smaller companies with limited budgets. By working together, these companies can leverage each other’s strengths and create innovative solutions that may not have been possible on their own.

Another advantage of joint ventures in additive manufacturing is the opportunity for knowledge exchange. With different companies bringing unique perspectives and experiences to the table, there is great potential for learning from one another and developing new techniques or processes.

Additionally, by forming partnerships through joint ventures rather than mergers or acquisitions, companies retain their independence while still reaping the benefits of collaboration. They are able to maintain control over their operations while gaining access to new markets or technologies through shared ownership.

However, it’s important for companies considering a joint venture in this industry to carefully evaluate potential partners before entering into an agreement. It’s crucial that both parties share similar values and goals in order for the partnership to be successful.

In conclusion,joint ventures offer numerous advantages when it comes to navigating the fast-paced world of additive manufacturing. By joining forces with other businesses in this field,you have accesss tp valuable resources,knowledge,and opportunities without sacrificing your company’s autonomy.This collaborative approach allows you stay ahead of competitors,maintain financial stability,and drive innovation within your respective industries.A well-planned and executed joint venture can truly be a game-changer in the additive manufacturing industry.

Understanding Joint Ventures in the Additive Manufacturing Industry

Joint ventures in the additive manufacturing industry have become increasingly common as companies seek to expand their capabilities and reach new markets. But what exactly is a joint venture, and how does it work in this particular industry?

A joint venture is a business agreement between two or more companies where they combine resources, expertise, and intellectual property to achieve a common goal. This can take various forms, such as a partnership, collaboration, or co-development project. In the context of additive manufacturing, joint ventures often involve companies from different sectors coming together to leverage their respective strengths and technologies.

One key benefit of joint ventures in the additive manufacturing industry is the ability for companies to access new markets and customers that they may not have been able to reach on their own. For example, an aerospace company may partner with a 3D printing company to develop specialized components for aircrafts. By combining their expertise and technologies, they can offer unique solutions that cater specifically to the needs of the aerospace market.

Another advantage of joint ventures in this industry is the sharing of knowledge and resources. As additive manufacturing technology continues to advance at a rapid pace, it can be challenging for one company alone to stay updated on all developments and innovations. Through partnerships with other companies in joint ventures, businesses can gain access to new ideas and techniques while also reducing costs associated with research and development.

In conclusion,joint ventures are becoming essential tools for growth within the additive manufacturing industry due to its numerous benefits such as expanding market reach and sharing knowledge/resources.This trend is likely continue as more businesses recognize its potential for success in this rapidly evolving field.

Fostering Partnerships: The Key Benefits of Joint Ventures in Additive Manufacturing

Fostering Partnerships: The Key Benefits of Joint Ventures in Additive Manufacturing

The realm of additive manufacturing is a vibrant, ever-expanding universe of innovation and possibility. It bristles with potential, but it’s also fraught with challenges that can often seem insurmountable if faced alone. So, enter the power of joint ventures: partnerships designed to combine unique skills, resources and strengths for mutual success.

The benefits are manifold. Shared risk is one significant advantage; when companies pair up to tackle a project, the financial pressure that might have been crippling for one becomes more manageable. They split not only costs but also any potential losses or setbacks.

In addition to shared risk, there’s also the vital element of pooled expertise. In these collaborations,

- creativity thrives,

- new ideas take flight,

- solutions emerge from unexpected angles.

We’re talking about teams comprised of experts from different niches within this sector joining forces – each member brings their own invaluable insights and specialized knowledge into play. This creates an enriched environment where learning is reciprocal and constant.

Finally – and perhaps most significantly – such strategic alliances can offer an accelerated pathway towards growth by facilitating access to new markets as well as enhanced competitiveness against larger rivals through shared infrastructure & technology platforms.

Through collaboration rather than competition we see how businesses can reach greater heights faster in the sphere of additive manufacturing via joint ventures.

Read also: Steve Cohen on venture capital

Exploring Case Studies: Successful Joint Ventures in the Additive Manufacturing Industry

The world of additive manufacturing, commonly known as 3D printing, is a dynamic and rapidly evolving industry. Successful joint ventures are helping to propel this space forward by driving innovation through collaboration and shared expertise. One such partnership that deserves our spotlight is the strategic alliance between GE Additive and Protolabs.

Born out of mutual respect for each other’s skills, GE Additive—a leader in industrial 3D printing equipment—and Protolabs—an on-demand manufacturer servicing multiple industries—joined forces to push the boundaries of what was possible in their field. This collaboration has resulted in countless successful projects, from cutting-edge medical implants to sophisticated aerospace components.

- Their combined strengths have made it possible to produce parts with complex geometries that would be nearly impossible using traditional methods.

- The joint venture also promotes more efficient utilization of materials while reducing waste dramatically.

- Moreover, speed-to-market has been notably enhanced due to streamlined production processes enabled by this alliance.

Within these inspiring collaborations thrives something truly exciting: an indisputable testament to the power of synergy and technological progress.

Another standout case study comes from two innovative giants; French multinational company Dassault Systèmes, renowned for its software development prowess in 3D design, and American tech titan Xerox Corporation. Their combined efforts are aiming at transforming conventional paper printers into full-blown high-resolution multi-material 3D printers.

By leveraging Dassault’s software expertise along with Xerox’s deep knowledge in advanced manufacturing technologies, they’ve successfully created a blueprint for crafting cost-effective custom products right at your desktop.

- This partnership has opened new doors for small businesses and creative individuals across the globe, allowing them to turn their ideas into tangible products without exorbitant costs.

- It has also accelerated the adaptation of 3D printing technology in everyday life by making it more accessible and easy-to-use for consumers.

These alliances serve as shining examples of how beneficial joint ventures can be in advancing additive manufacturing. It shows us that when ambitious businesses combine forces, they create fertile ground for groundbreaking innovation.

Overcoming Challenges and Risks Associated with Joint Ventures in Additive Manufacturing

In the additive manufacturing realm, joint ventures can provide an exciting platform for innovation and growth. The magic happens when two or more organizations come together combining their skills, resources, and technologies to create something extraordinary they couldn’t have managed alone. However, despite its glittering allure, joint ventures aren’t without stumbling blocks; risks like intellectual property theft and profit-sharing disputes lurk behind every corner.

To start with a classic case of ‘too many cooks in the kitchen’, disagreements over profit splits can quickly escalate into full-fledged legal battles that drain time, money and morale. But this doesn’t mean you should shy away from partnerships altogether! A well-drafted contract spelling out ownership rights and revenue distribution can keep such tensions at bay. Additionally,

- Prioritizing open communication: Encouraging transparency prevents misunderstandings from ballooning into bigger issues.

- Nurturing a culture of mutual respect: This fosters positive relations between partners which are essential for collaboration.

- Maintaining flexibility: Adapting to unforeseen changes swiftly keeps the venture moving forward smoothly.

Another major concern is intellectual property (IP) protection – after all, ideas are invaluable in our industry! As you divulge your coveted manufacturing secrets during collaborations, there’s always a risk they could fall into unscrupulous hands leading to IP thefts. To safeguard against this perilous pitfall:

- Create robust non-disclosure agreements (NDAs): These legally binding contracts bar partners from disclosing sensitive information without explicit consent.

- Leverage patent protections: Patents grant exclusive rights to your inventions stopping competitors from copying them outrightly.

So yes – while challenges exist in the realm of joint ventures, they’re no reason to sideline potential collaborations. With careful planning and thoughtful strategies, you can navigate these hurdles and harness the power of collaboration for your additive manufacturing endeavors!

joint ventures in additive manufacturing industry

joint ventures in additive manufacturing industry

You may also like: What Mukesh Ambani thinks about venture capital

Strategies for Establishing Effective Joint Ventures within the Additive Manufacturing Sector

Establishing a successful joint venture within the additive manufacturing sector requires careful planning, mutual understanding and solid strategies. Research is the first crucial step; ensure you understand your potential partner’s business model, goals and financial stability thoroughly. Joint ventures can be complex but they are worth the effort when both parties have complementary strengths and resources to bring to the table.

Additionally, it’s essential to take note of a few key points for an effective joint venture:

- Shared Vision: Both parties must agree on common objectives for their alliance. This fosters harmony and prevents conflicts in decision-making processes.

- Mutual Respect & Trust: Each party should respect each other’s contribution towards achieving shared goals. A high level of trust is vital for mitigating risks associated with knowledge sharing.

- Cultural Compatibility:Cross-cultural differences may impact how partners behave or view certain issues. It’s essential for partners to understand each other’s corporate cultures and find middle ground when necessary.

Remember that flexibility is paramount in any joint venture agreement – needs may change as businesses evolve over time.

In conclusion, establishing effective joint ventures within the additive manufacturing sector isn’t about luck – it necessitates diligent research, meticulous planning, alignment of visions between partners with mutual respect & trust at its core. These alliances can open doors to new markets while fostering innovation through collaborative efforts – proving beneficial not only on individual levels but also contributing significantly towards industry development.

Conclusion: Maximizing Growth Potential Through Joint Ventures in the Additive Manufacturing Industry

In the fast-paced world of additive manufacturing, a single company might not have all the resources or expertise to fully utilize its growth potential. That’s where joint ventures come into play as a solid strategy for maximizing growth. Joint ventures are super-charged partnerships between two or more businesses that aim to achieve specific goals while sharing profits – and losses equally. With shared resources, complementary skills, and combined funding, these alliances can take businesses to new heights they would struggle to reach alone.

Joint ventures in the additive manufacturing industry specifically facilitate an environment ripe for innovation and progress. A hardware manufacturer might partner with a software developer to create integrated solutions that revolutionize 3D printing capabilities; another joint venture could see materials suppliers teaming up with design firms on groundbreaking products leveraging cutting-edge techniques like selective laser sintering (SLS) or direct metal laser sintering (DMLS). Using these techniques:

- New product forms are possible,

- Efficiency gains can be significant,

- Costs may drop significantly.

These meaningful collaborations unlock untapped markets, spread risk effectively among partners, and pave the way for exponential technological advancements in this rapidly evolving field of manufacturing technology.

Read also: jv company